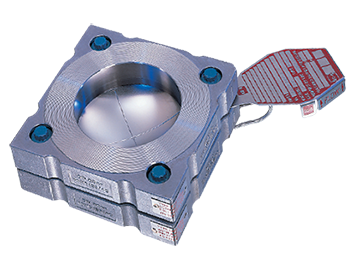

Model SRB-7RS-TR™ Safety Head

The Type TR™ Series Torque Resistant Safety Head offers the identical performance and flow characteristics as those of standard BS&B safety heads. The only difference – the TR Series Safety Heads were designed with features which make them forgiving of the real world environment associated with modern process applications. Misaligned, non-parallel, and improperly spaced flanges create uneven hold down forces on rupture disk devices when installed. Additionally, installation instructions have typically recommended the use of compressed fiber (sheet) gaskets for rupture disk installations. Many customers, however, prefer metal spiral wound gaskets which, in order to effectively energize the seal on those designs, require torque well in excess of rupture disk manufacturer recommended values. The excessive force associated with spiral wound gasket torque and the uneven forces associated with misaligned, non-parallel, and unevenly spaced flanges can have dramatic effect on rupture disk life and performance, resulting in rupture disk activation outside of stated tolerance.

The modified disk-holder interface reduces the influence of excessive or uneven torque transmitted to the disk during installation and allows the safety heads to utilize the torque values associated with standard metal spiral wound gaskets. There is no difference in flow path (same Kr) or face to face dimensions of BS&B standard holders and the TR™ versions of those holders, meaning no Management of Change/Change of Design and no piping modifications are required to upgrade to the TR version of any existing BS&B flat seat holder.